Click here

for a sheet listing recommended radio gear for the foamies.

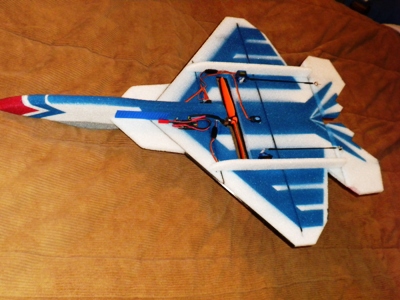

Our latest try at club pylon racing is to race a foamie F22 Raptor 90% sized. The rules are simple:

1. Airframe: F22 Raptor constructed from 9 mm EPP foam. Plans are below, we are racing a 90% version. This allows the equipment below to be used.

2. Engine: blue wonder or silver wonder, size 2730-1500.

3. 8x4 GWS prop.

4. Battery: Rhino 610 Mah 3 cell lipo

5. Minimum weight: 8.3 oz

6. Speed Control: your choice, most are using the 10A or 12 A from the places below. They are inexpensive and have built in BEC.

All parts are available from Heads Up RC, Hobby City in China (thier USA warehouse has some), RC Foam or from Western Michigan Park Flyers. There may also be some other places, however, Ralph, Bryan and others have had successs with these places. Ralph has done some research and provided the RCFoam links below.

Heads Up Rc has most everything needed and are very reasonable to ship and really fast.,

Western Michigan Park Flyers has all the equipment you will need,

Hobby City has motors, speed controls, servos and props.

We will keep adding to this page. Typical builds are using 9 gram servos on the elevons and six gram on the rudders for the 24" wing span. For the 90% F-22, you can use 5 or 6 gram servos on everything if you wish. Ralph's Blue Angel and Parker's Thunderbird 1 use all 5 gram servos. You can choose to build with or without rudders. All glue used is hot melt glue for main contruction and welders cement (rubber contact cement for hinging. Most use carbon fiber rods for the pushrods and just about anything can be used for control horns. Pictured below are details from mine.

Click here

for full sized (24" wing span plans)

Here are some build pictures, click on then for a larger view:

1. A shot of the rudders and rudder servo, this is a 5 gram servo. The control horns are Dubro micro horns (Dubro # 919), although any control horn will work. I used Dubro mini ez connectors (Dubro # 845) on the rudder end to make centering easier since one servo drives both rudders.

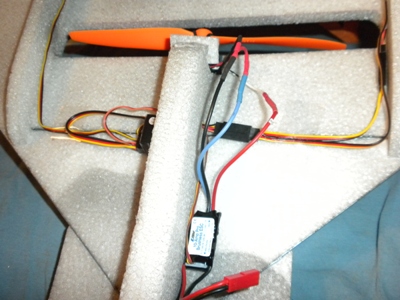

2. Top view of the motor mount using the mount from NWPark Flyers or Hobby City. The motor bolts to a round adapter which is then inserted into the tube and a set screw tightened to retain it. Some also use a small approximate 1"x1" plywood firewall.

3. Shot of the underside radio "compartment" showing the speed control, receiver and motor. Be sure to tape or silicone or even use a drop of hot melt glue to keep servo wires from getting into the prop. The battery is mounted towards the nose.

4. Elevon servos layout. Also, look at the photo at the top of the page, it shows the servos on the underside. When setting up the tail servos, you will need to use elevon or delta wing mode.

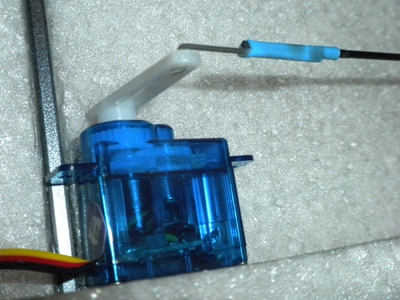

5. Close up of the elevon servo and pushrod. The servo is laid on it's side and glued directly to the foam. If you mount this way, rough up the servo case with light sand paper. Ralph mounts his elevon servos traditionally from the top by cutting a slot just the size for the servo. The pushrod is .060" carbon fiber with .032" music wire bent into a Z Bend and then heat shrink wrapped together. I also use a drop of CA glue before shrinking the shrink wrap. Here again, just about anything will work. TIP: if you use hot melt glue to attach the servos and they need ot be removed, drip rubbing alcohol around the servo. Let it set for a while and it will soften the hot melt glue and you will be able to remove it without destroying the foam.

6. This shot is of the control surface end of the elevon rod. I used control horns from a former electric flyer, again about any control horn will work.

7. Another shot looking at the rudder servo installation.

Pylon race 1

Pylon race 2

Ralph McBee flying some pylon race laps with his 90%'er.

Rege Hall flying his 24" wing span F-22, cool plane!